Table Of Content

For more sophisticated products, this time frame may be extended to three or even four weeks. The length of the DFM process is influenced by factors such as the complexity of the product, the resources available, the experience of the design and manufacturing teams, and the size of the organization. The time required for design for manufacturability is determined by the product’s complexity, the organization’s size, and the resources available. However, as a general rule, DFM is a continuous process that begins at the initial stages of product design and continues through the entire product lifecycle. The need to comply with regulations, such as environmental regulations or product safety standards, can impact the design and production processes and add costs. The cost of labor can significantly impact the production process’s overall cost, especially in labor-intensive manufacturing processes.

DFM Software Should Be Fast And Easy To Use

The incorporation of Design for Assembly (DFA) concepts into DFM is another significant development. By standardizing components, reducing the number of parts and providing for simple handling and alignment during assembly, DFA aims to simplify product assembly. Companies like Toyota use DFA methods to simplify assembly processes and cut labor costs while also producing higher-quality products.

3D Printing

For example, by keeping injection molding restrictions in mind early on, such as avoiding complicated component geometries and limiting undercuts, a DFM approach helps keep design revisions affordable and on track. In a similar vein, optimizing sheet metal designs with suitable bend radii and nesting considerations can help head off production issues, cutting down on iterations and reworking later on. Product designers, product engineers, or manufacturing engineers will benefit by attending this course. Individuals involved in a new or ongoing product development process will also benefit by learning how to help synchronize and optimize fabrication and assembly activities. This course is most effective when attended by product development team members; however, this is not a requirement for attendance.

Uses and Examples of DFM for Different Manufacturing Processes

A modular design means that the product assembly is divided into different sub-assemblies (modules) that can easily be changed without affecting the design of other modules. It is clear from the discussion above that design for manufacturing is a very goal-oriented approach and it encompasses multiple objectives. Achieving all of these, while also balancing them against project limitations, is a complex problem. For example, if the enclosure is meant for low-cost electronics, a simple plastic enclosure will do.

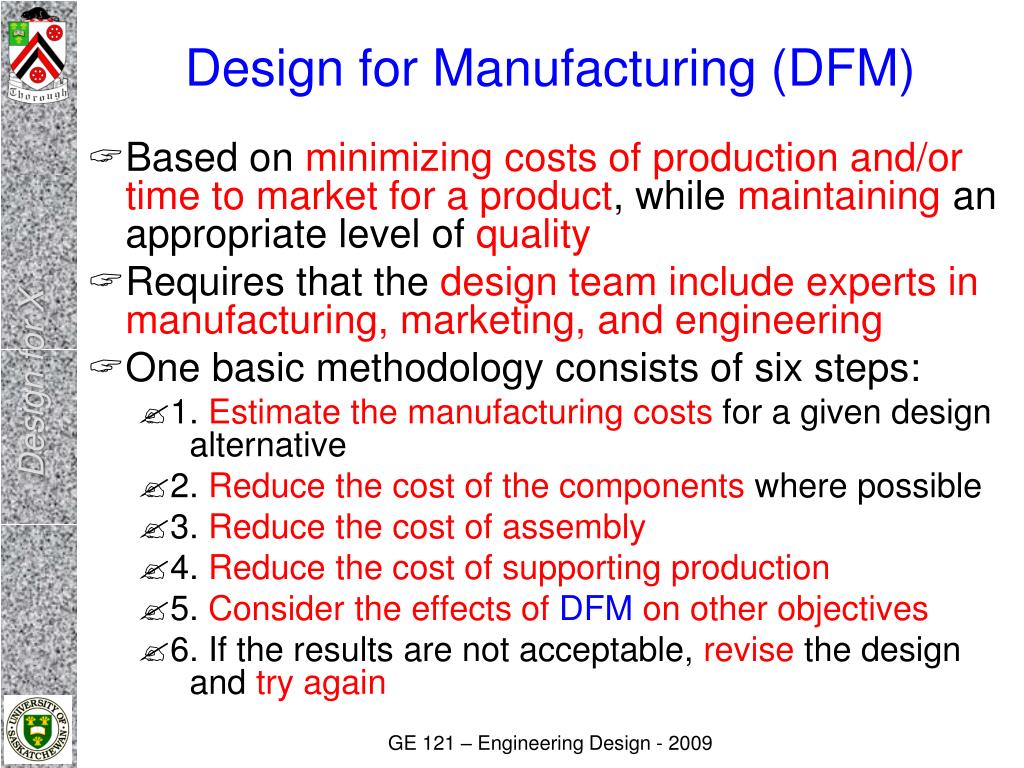

DFM includes several concepts, including choosing easily obtainable and reasonably priced materials, reducing the number of parts, and designing with simplicity of assembly in mind. For any business looking to make money and create products that are profitable, DFM is vital for efficiency, speed, and high rates of production. It is thought that approximately 70% of the manufacturing costs of a product derive from design decisions made in the early design stages, such as materials used or method of manufacturing. A focus on the design stage, available through DFM, would significantly reduce the final production cost. It can also enable the identification, quantification and elimination of waste or inefficiencies at various points throughout the manufacture and production process. It may additionally be used as a method of benchmarking and, in doing so, a company can assess the products of competitors.

Design for Assembly (DFA)

The technology developed includes eight machining operations, as well as marking, fitting, and monitoring. APriori provides a unique, end-to-end digital twin solution that empowers manufacturers to unlock and identify new opportunities rapidly for innovation, growth, cost savings, and sustainability. With aPriori, customers achieve a ~600% ROI and payback within six months of adopting our software platform. And companies use our automated manufacturing insights to eliminate product cost, improve productivity, and reduce their products’ carbon footprint.

This approach makes product upgrades during the prototype development phase very easy to achieve. Moreover, it puts the entire design process in a more systematic framework where design engineers can conveniently pinpoint exact modules to work on without concern for overall functionality. This goal is set to ensure that the production is in line with modern sustainability goals stemming from environmental concerns and over-consumption of limited sources. Another objective of design for manufacturing is to maximize the quality of the product.

Such an advanced manufacturing simulation was once a pipe dream due to the lack of available tools and manufacturing processes. DFM helps us analyse the different aspects of design and manufacturing processes in the light of many prudent principles. It provides new ideas and techniques to bring about a positive change in product design to benefit all the involved parties (designer, manufacturer and customer).

Disadvantages of DfMA

In effect, it is less time-consuming, which improves the time-to-market for a new product. When following DFM procedures it is recommended to test the product design for compliance before mass production begins. Waiting until the very end of the product development process can bring huge costs and may even require the product to be taken back to the design stage.

To better prepare for surgery, 3D printed models mimic the anatomy, size, texture and color of real organs, tissues and lesions. The last step in cultivating a DFM mindset is to encourage engineering and design teams to train and educate themselves on DFM concepts. This means employers must provide resources, courses and case studies that highlight good DFM processes. Ultimately, DFM is a collaborative effort that benefits significantly from the expertise of all involved parties. By recognizing and leveraging the insights of suppliers, businesses can make DFM a more effective strategy, improving their overall product development process. A product that is designed with manufacturing in mind will be easier to assemble and more reliable, leading to higher quality and fewer returns.

Design and Manufacturing Services Solution Brief - White Paper - All About Circuits

Design and Manufacturing Services Solution Brief - White Paper.

Posted: Fri, 22 Mar 2024 16:43:57 GMT [source]

Those set to succeed are doing so holistically and from the very start of their development processes. Designers are sometimes hesitant to experiment with prototypes, as producing a single part or assembly with traditional materials and techniques is both expensive and time-consuming. In practice, this implies that the DFM process is often a negotiation of sorts between design intent and the practicalities of making products at scale in a cost-effective manner. To leave no stone unturned in this analysis, DFM software should be comprehensive, with the ability to estimate manufacturability implications ranging from production and labor to distribution. But even the most comprehensive analysis won’t unlock the benefits discussed in the guide if it’s not applicable in the context of a fast-paced, collaborative design effort. Design for assembly refers to designing a product to maximize how easily it can be assembled and disassembled for repairs and maintenance.

Innovative materials and geometries used to meet sustainability targets might require more thorough testing to characterize performance. Simultaneously, new data and understanding of physical phenomena can be used to validate the simulation models used in design, or even optimize them through AI-enhanced reduced order models (ROMs). And data collected from the field or at the end of a product’s life can uncover novel situations, or edge-cases, to refine the digital twin for the next iteration.

The principles of design for manufacturing are guidelines that help ensure that a product is designed and made in the best way possible so that it can be made quickly and cost-effectively. Design for Manufacturing (DFM), also known as Design for Fabrication (DFF), is the engineering practice of designing products to facilitate the manufacturing process and reduce manufacturing costs. It means taking actual manufacturing capabilities into account when creating a product design and reviewing designs to ensure that they meet manufacturing specifications. By designing a product with manufacturing in mind, designers can ensure that the product is easy to manufacture, reducing production costs and improving quality. DFM also allows designers to work closely with manufacturing teams, ensuring that the product is designed in a way that makes it easy to manufacture. Poorly designed products can be difficult or expensive to manufacture, increasing production costs and reducing profitability.

DFX allows us to select a focus area for the design so that product objectives can be achieved. Design For Manufacturing in particular helps to achieve design simplicity and reduce manufacturing costs which usually account for the largest portion of investments for a company. Design for manufacturability ensures that the product meets the quality standards set in the design phase. It makes sure that the performance, surface finish, tolerances, reliability, aesthetics, conformance, features, durability, serviceability and perceived quality of the product match the target specifications. Such a cost-effective operation can in turn improve profitability by increasing the ROI.

No comments:

Post a Comment